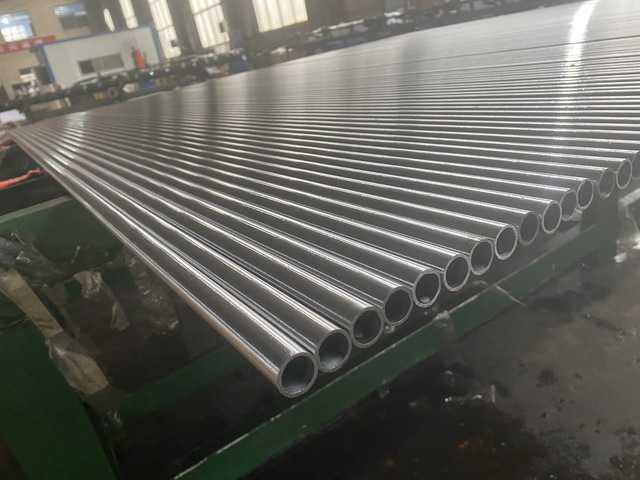

Products Introduction

Precision bright steel tube is a kind of high-precision steel tube material through precision drawing or cold rolling treatment. Because of the precision bright tube inside and outside the wall without oxide layer, bear high pressure without leakage, high precision, high finish, cold bending without deformation, flaring, flattening without cracks and so on, so mainly used for the production of pneumatic or hydraulic components of the product, such as cylinders or cylinders, can be seamless tubes, there are welded tubes. The chemical composition of precision bright tube has carbon C, silicon Si, manganese Mn, sulfur S, phosphorus P, chromium Cr.

Features

Steel tube inner and outer wall high precision, high finish, no oxidation layer of steel tube after heat treatment, high cleanliness of the inner wall, steel tube to withstand high pressure, cold bending without deformation, flaring, flattening without cracks, precision steel tubes can be made of a variety of complex deformations and mechanical processing treatment. Tube color: white with bright, with high metal luster.

Applications

Automobiles, mechanical parts and other machinery that have high requirements for the precision and finish of steel tubes. Precision steel tube users are not only the accuracy, finish requirements of the user is relatively high, because of precision bright tube high precision, tolerance can be maintained at 2-8 silk, so many mechanical processing users in order to save the work, material, time loss, seamless steel tube or round steel is slowly transformed into precision bright tube.

Commonly Used Materials:

10#, 20#, 35#, 45#, 40cr, 25Mn, 37Mn and so on.