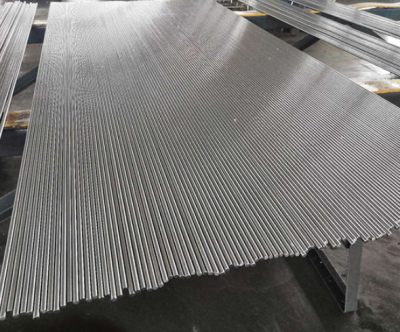

Quenched And Tempered Bright Steel Bar

High Precision: Ensures accurate and consistent tolerances for superior quality.

Smooth Surface: Provides a smooth, glossy finish for enhanced functionality and appearance.

Material Savings: Tight tolerances and a polished surface minimize material waste, leading to significant savings, especially with large quantities.

Time & Machinery Savings: High precision and excellent surface quality enable direct use in processes like spraying, sanding, bending, and drilling, reducing machining time and equipment costs.

Products Introduction

Abrasive steel rod is a metal disk or bar after spheroidal annealing, drawing, straightening, chamfering, cutting, grinding and a series of processing technology made of precision, straightness, roundness, etc. have reached the corresponding requirements of the bar, is the production of high-precision shafts, rods, turned parts, standard parts and other mechanical transmission components required for the important materials. Generally according to the end use and the production of parts on the precision grinding rod size accuracy, surface quality, straightness, mechanical properties of the material and other requirements to determine the required metal material and processing technology.

Features

High precision: ensure accurate and uniform tolerances.

Smooth surface: smooth and bright surface.

Large savings in material: small tolerances, bright surface, so that the depletion of raw materials is minimal, relative to the use of traditional lathe machining cutting of materials consumed, the savings in material and time is very considerable, especially when the material dosage is large, the savings in material costs are more significant.

Processing time and processing machinery savings: due to accurate precision, good surface condition, can be used directly, such as spraying, sanding, bending, drilling, eliminating a large number of machining time and save the cost of configuring processing machinery.

Classifications

Grinding rods can be categorized into carbon and stainless steel, copper and related alloys, pure titanium and titanium alloys, other metals and alloys, etc. according to the material.

Specifications

Commonly used materials | Commonly used delivery status | Common technical indicators |

Q235 45# 40Cr 42CrMo GCr15 2Cr13 4Cr13 17-4 60Si2Mn etc. | Φ8~40mmcold-drawn bar, cold-drawn strip Φ8~40mmbare round (peeling processing) Φ8~40mmtempered round Φ8~40mm fine-drawing tempered bar Φ8~40mmtempered grinding barΦ8~40mmtempered polished bar Φ8~40mm tempered grinding and polishing rods Φ8~40mmchrome plated hard shaft Φ8~40mmchrome plated flexible shaft The rest of the sizes can be customized. | Tolerance of the diameter of peeled or cold-drawn material≤0.05mm Grinding or polishing material diameter tolerance≤0.02mm Straightness≤0.2mm/m Fineness Ra0.4~0.8 Length3m/3.03m/2.5m/customizable Hardness can be customized according to requirements Packing: woven bag, hollow board, geotextile, wooden box, etc.

|

Applications

Grinding rods are mainly used in CNC machine tools, automobiles, medical equipment, printing instruments, power tools and hardware electromechanical, engineering machinery, railroad locomotives, home appliances and other equipment with shafts, worm gears, connecting rods, precision bearings, transmission rods, screws, standard parts, turned parts and other mechanical transmission parts manufacturing industry.